本生产线用于白色填料矿物的超细加工,其中包括石灰石、方解石、大理石、白云石、白垩、以及重晶石、滑石、高岭土、氧化镁等。

● 采用德国IVA设计理念和计算方法,对工艺和设备进行定制化设计;

● 优化驱动设计,磨机电机和设计能力相匹配,最大限度地节省能耗;

● 优化磨机长径比,无过磨或涨磨现象,提高了研磨效率可节能5-8%;

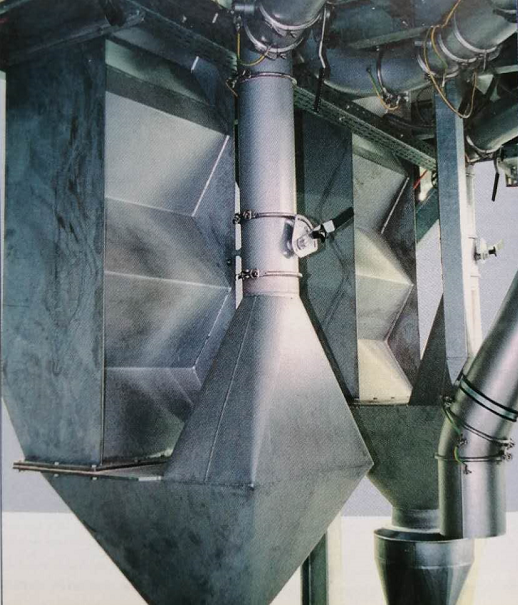

● 磨机尾端设置除尘机构,即可除尘,又可在磨机中实现产品预分级;

● 采用cylpebs研磨体,高填充率,改变了研磨机理,提高细粉含量;

● 球磨机带有料位指示计可对磨机进行自动控制,确保产品质量稳定性;

● 公本司专利分级机,顶定点切割清晰,可满足不同粒度分布要求;

● 整条生产线采用负压闭路循环系统,无粉尘,符合国家环保标准。

1, Grinding and classifying production line of calcium carbonate and other white mineral fillers

This production line is used for ultra-fine processing of white mineral fillers, which include limestone, calcite, marble, dolomite, chalk, and barite, talc, kaolin, magnesium oxide, etc.

● Customized process and equipment designed with German IVA design concepts and calculation methods.

● Optimized driving station matched with product fineness and capacity results in maximum energy saving.

● Optimization of mill length to diameter ratio avoids over-grinding or running dead of the mill and improves grinding efficiency by 5-8%.

● Dust removal outlet installed at the end of the mill not only remove the dust but also yields pre-classified product from the mill.

● Application of cylpebs with high filling rate and more friction results in increasing of fine powder content.

● The ball mill can installed with a level indicator for automatic control, which can ensure the stability of product quality.

● The patent classifier of our company offers clear top cut, that can meet the requirements of different product fineness.

● The whole production line works in negative pressure environment and a closed-circuit circulation release no dust

通过

通过