| 材质 | 金刚石 |

|---|---|

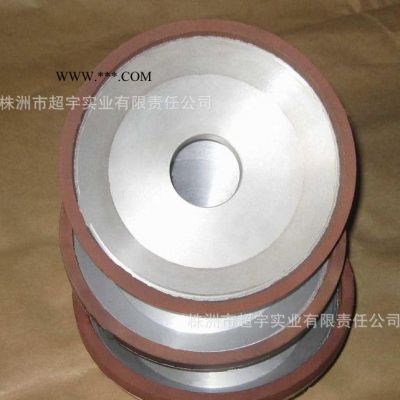

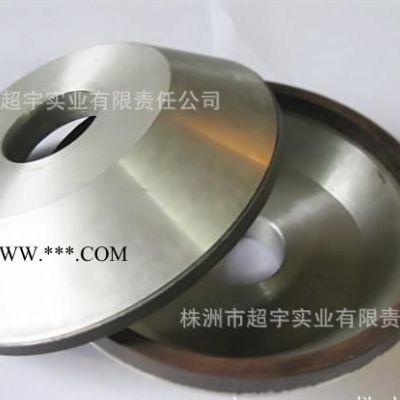

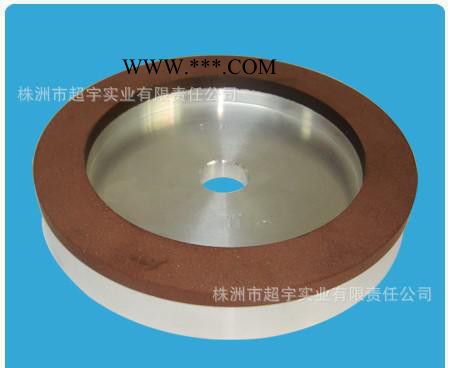

| 结合剂 | 树脂砂轮 |

| 粒度 | 客户选择(目) |

| 形状 | 碗型 |

| 工艺 | 烧结 |

| 适用范围 | 刀具的刃磨 |

| 圆度< | 如下表 |

| 圆柱度< | 如下表 |

| 加工定制 | 是 |

| 规格 | 如下表 |

| 类型 | 平面磨砂轮 |

| 工作线速度 | 如下表 |

| 品牌 | 超宇 |

| 型号 | 12A2/45 |

| 磨粒granularity | 微粉micro-powder | ||||

| 粒度号Number | 粒度尺寸Dimension | 粒度号Number | 粒度尺寸Dimension | 粒度号Number | 粒度尺寸Dimension |

| 35 | 500~400 | 120 | 125~100 | W40 | 40~28 |

| 45 | 400~315 | 150 | 100~80 | W28 | 28~20 |

| 60 | 315~250 | 180 | 80~63 | W20 | 20~14 |

| 70 | 250~200 | 240 | 63~50 | W14 | 14~10 |

| 80 | 200~160 | 280 | 50~40 | W10 | 10~7 |

| 100 | 160~125 | 320 | 40~28 | W7 | 7~5 |

| 粒度Granularity | 硬质合金工件表面粗糙度Surface coarseness of cemented carbide workpiece | 磨削工序grinding procedure | |||

| 树脂结合剂B | 金属结合剂M | ||||

| 60/70~100/120 | 1~4 | 粗磨 | rough | ||

| 100/120~140/170 | 0.4~0.2 | 0.8~0.2 | 半精磨 | semi-finishing | |

| 140/170~230/270 | 0.2~0.1 | 0.4~0.2 | 精磨 | finishing | |

| 270/325~W20 | 0.1~0.05 | ~ | 精磨 | finishing | |

| W14~W5 | 0.05~0.025 | ~ | 研磨 | super grinding | |

| W5~W1 | 0.025~0.012 | ~ | 研磨 | super grinding | |

| Diamension(mm) | Diamond content/pcs | |||||||

| D | H | d | W | X | R | 50% | 75% | ** |

| 50 | 25 | 10 | 2.5 | 5 | 4 | 6 | 8 | |

| 75 | 32 | 20 | 3 | 5 | 7.3 | 10.95 | 14.6 | |

| 80 | 32 | 20 | 3.5 | 5 | 9.05 | 13.58 | 18.1 | |

| 100 | 40 | 20 | 3.5 | 7 | 15.9 | 23.85 | 31.8 | |

| 125 | 40 | 32 | 3.5 | 7 | 20.25 | 30.38 | 40.5 | |

| 150 | 45 | 32 | 5 | 7 | 34.5 | 51.7 | 68.95 | |

| 125 | 45 | 32 | 2.5 | 7 | 14.4 | 21.6 | 28.8 | |