| 固定碳 | 99 |

|---|---|

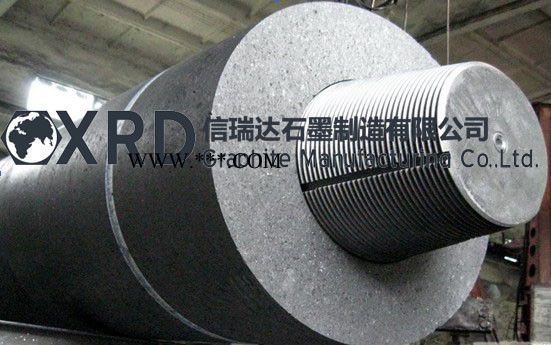

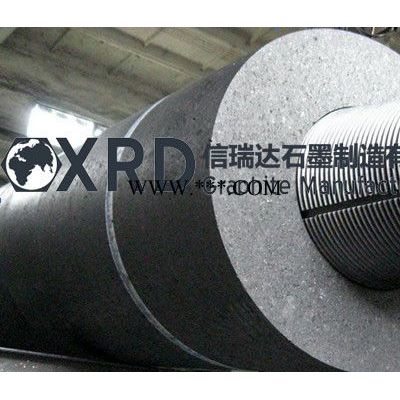

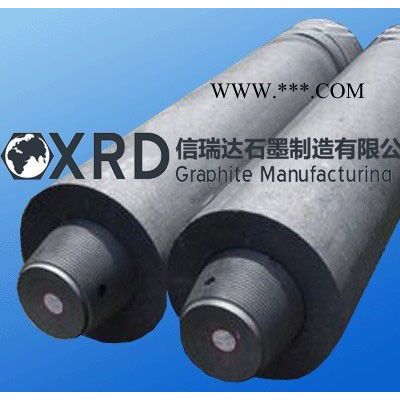

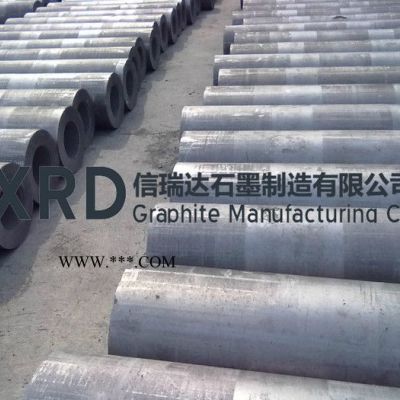

| 品名 | 石墨电极 |

| 规格 | 800 |

| 型号 | 模压 |

| 牌号 | 信瑞达 |

| 水分 | 0.05 |

| 膨胀度 | 0.1 |

| 筛上物粒度 | 98 |

| 灰分 | 0.1 |

| 挥发分 | 0.1 |

| 筛下物粒度 | 0.2 |

石墨电极优势 一、速度快; 石墨放电比铜快2-3倍,材料不易变形,在薄筋电极的加工上优势明显,铜的软化点在1000度左右,容易因受热而产生变形,相比而言,石墨材料热膨胀系数只有铜材的1/30; 二、重量轻; 石墨的密度只有铜的1/5,大型电极进行放电加工时,能有效降低机床(EDM)的负担,更适用于大型模具的应用; 三、损耗小; 由于火花油中含有C原子,在放电加工时,高温导致火花油中的C原子被分解出来,而在石墨电极的表面形成保护膜,补偿了石墨电极的损耗;

Graphite electrode advantages :First, the high speed; Graphite discharge 2-3 times faster than copper, the material is not easy to deformation, obvious advantages on thin steel electrode processing, the softening point of copper in 1000 degrees, easy to produce because of the heat deformation, by contrast, only 1/30 of the copper graphite material coefficient of thermal expansion; Second, the light weight; The density of graphite is only 1/5 of copper, large electrode in EDM, can effectively reduce the burden of machine tools (EDM), more suitable for the application of large injection mould are; Three, small loss; Because the spark oil contains C atoms, in edm, high temperature lead to spark came out of the oil C atoms are broken down, and on the surface of graphite electrode form a protective film, compensate the loss of the graphite electrode.